CNC machines

APM’s has 3- and 5-axis CNC machines with varying work envelopes in the X-axis from 800 mm up to 3000 mm.

Machine: DMU 125 monoBLOCK.

Working area: 5-axis machining Ø 1440×790 mm.

Control system: Heidenhein iTNC 530 HSCI.

Machine feeds: 0-30m/min.

Spindle speed: Max 24 000 R/min, cone HSK A63.

CAD/CAM system: Tebis.

Areas of use: Design and verification milling in plastic and aluminium, as well as heavier form machining in steel.

Other information: Machine table area, 1400×1000 mm. Maximum load, 2000 kg.

Supplier: DMG/Mori Seiki Sweden AB.

Machine: FAMU Active Five 3000 5-axis.

Working area: Vertical machining X3000, Y1300, Z850, 5-axis machining X2200, Y1000 (100 mm tool length).

Control system: Heidenhain iTNC 530.

Machine feeds: 0-30m/min.

Spindle speed: Max 22 000 R/min, cone HSK A63.

CAD/CAM system: Tebis.

Areas of use: Design and verification milling in plastic and aluminium, as well as heavier form machining in steel.

Other information: Machine table area, 3100×1100 mm. Maximum load, 5000 kg.

Supplier: Gruppo Parpas, (Italy).

Machine: FAMU Active Five 2000 5-axis.

Working area: Vertical machining X2000 Y1300 Z1000, 5-axis machining X1200 Y1000 Z760 (100 mm tool length).

Control system: Heidenhain iTNC 530.

Machine feeds: 0-30m/min.

Spindle speed: 22000 rpm; 30kW; HSK A63.

CAD/CAM system: Tebis.

Areas of use: Design and verification milling, we process in plastic, aluminium and steel.

Other information: Machine table area, 2100×1100 mm. Maximum load, 3000 kg.

Supplier: Gruppo Parpas, (Italy).

Machine: DECKEL-MAHO DMU 80 monoBLOCK.

Working area: Vertical machining X880 Y630 Z630, 5-axis machining X680 Y680 (100 mm tool length).

Control system: Heidenhain iTNC 530.

Machine feeds: 0-30m/min.

Spindle speed: Max 24 000 R/min.

CAD/CAM system: Tebis.

Areas of use: Form milling in plastic, aluminium and steel.

Other information: The machine is fitted with a tool changer and equipment for tool scaling/control with a laser and measurement probe.

Supplier: DMG Scandinavia AB.

Machine: FAMU PHS 916.

Working area: Vertical machining X1600 Y920 Z600, 5-axis machining X1200 Y800 (100 mm tool length).

Control system: Heidenhain iTNC 530.

Machine feeds: 0-30m/min.

Spindle speed: Max 30 000 R/min.

CAD/CAM system: Tebis.

Areas of use: Design and verification milling in plastic and aluminium.

Other information: The machine is fitted with a tool changer and equipment for tool scaling/control with a laser and measurement probe.

Supplier: Gruppo Parpas, (Italy).

Machine: AVIA VMC 1000.

Working area: Vertical machining X1000 Y540 Z620.

Control system: Heidenhain iTNC 530.

Machine feeds: 0-30m/min.

Spindle speed: Max 10 000 R/min.

CAD/CAM system: Tebis.

Areas of use: Machining in plastic, aluminium and steel.

Other information: The machine is fitted with a tool changer and equipment for tool scaling/control with a laser and measurement probe.

Supplier: Avia, (Poland).

Machine: AVIA VMC 650.

Working area: Vertical machining X650 Y540 Z620.

Control system: Heidenhain iTNC 530 HSCI.

Machine feeds: 0-35m/min.

Spindle speed: Max 10 000 R/min.

CAD/CAM system: Tebis.

Areas of use: Machining in plastic, aluminium and steel.

Other information: The machine is fitted with a tool changer and equipment for tool scaling/control with a laser and measurement probe.

Supplier: Avia, (Poland).

Measuring machines

APM has three bridge-type measuring machines. They offer high accuracy and a measurement range of up to 2600 x 1500 mm. We use PC-DMIS measurement software.

Machine: DEA Global Image.

Measurement area: X1500 Y2600 Z1350.

Meas. system: PC-Dmis.

Meas. accuracy: 4,0+L/250 µm (i.e. 8,0 µm at 1000mm).

Machine:DEA Global Performance.

Measurement area: X1200 Y2200 Z1000.

Meas. system: PC-Dmis.

Meas. accuracy: 2,5+3L/1000 µm (i.e. 2,5 µm at 1000mm).

Machine: DEA Global Image.

Measurement area:X900 Y2000 Z800.

Meas. system: PC-Dmis.

Meas. accuracy:1,9+L/333 µm (i.e. 4,9 µm at 1000mm).

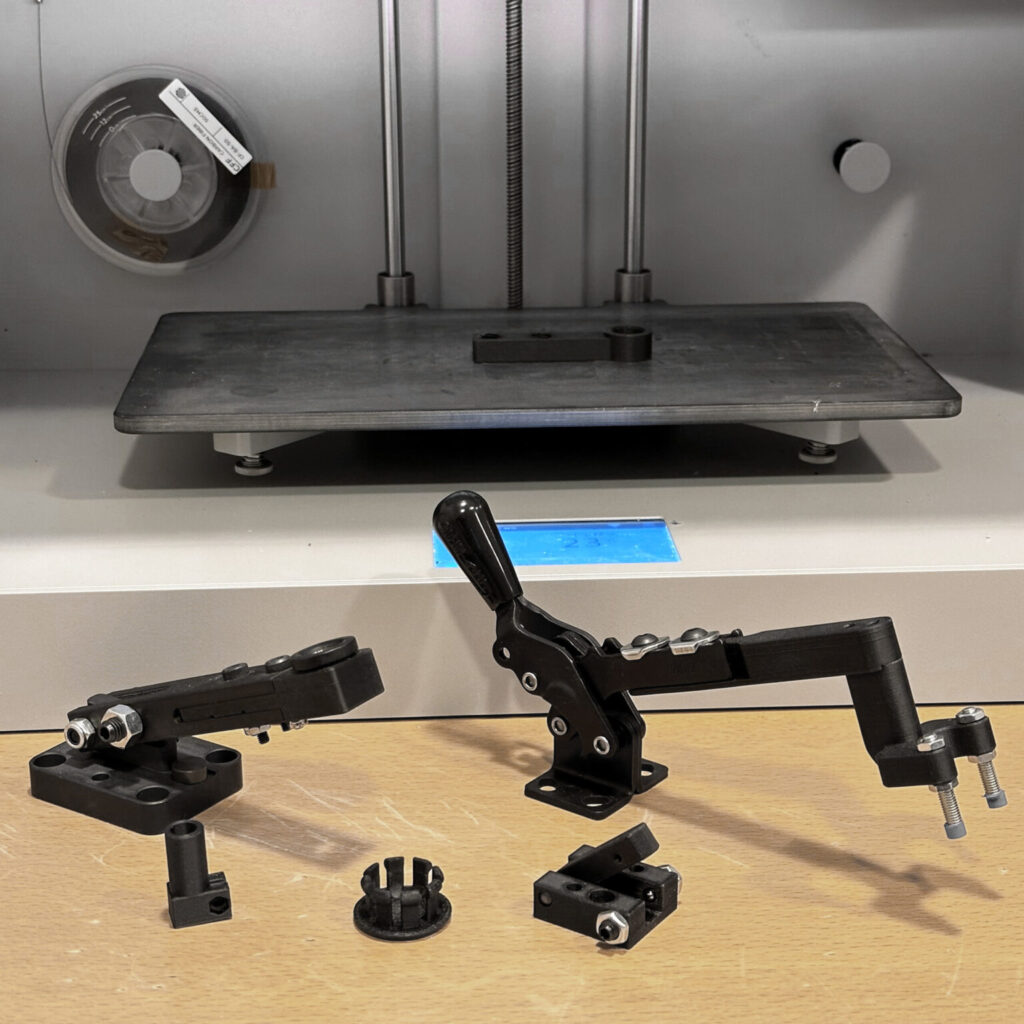

Design

At APM, we carry out design and surface modelling work in CATIA V5 software and use the CAM program Tebis for CNC programming. The team has more than 30 years’ experience of design and manufacture of measurement and control fixtures.

- Control equipment, fixtures, models, and tools

- Design and surface modelling are carried out in CATIA V5.

- 3D-printer (Markforged Mark Two) for the manufacture of details and functions in the material Onyx™. Onyx™ can be reinforced with continuous carbon fibres to achieve material properties comparable to aluminium 6082.

CAD-design Catia v5

PC-DMIS

3D-printing

CAM-preparation in Tebis V4.1